Aluminum Die Casting Part Manufacturers

The Importance of Aluminum Die Casting Parts

When it comes to home and garden appliances, the quality and durability of the components used play a significant role in ensuring optimum performance and longevity. Aluminum die casting parts have emerged as a popular choice due to their versatility, lightweight nature, and exceptional strength-to-weight ratio. These parts are widely used in various industries, including automotive, aerospace, electronics, and more.

Introducing Wetron Industrial

At Wetron Industrial, we take pride in being one of the leading aluminum die casting part manufacturers in the industry. With years of expertise and advanced manufacturing capabilities, we specialize in producing high-quality die-cast components that meet the stringent requirements of our clients.

Our Manufacturing Process

Our manufacturing process begins with the meticulous selection of premium-grade aluminum alloys. These alloys are known for their excellent strength, corrosion resistance, and thermal conductivity. By utilizing state-of-the-art die casting machinery and cutting-edge technologies, we are able to create precise and intricate parts that meet the highest industry standards.

Alloy Melting and Preparation

First, we carefully melt the chosen aluminum alloy in our advanced furnaces, ensuring optimal alloy composition and purity. It is during this critical phase that the characteristics of the final product are largely determined.

Dies and Molds Creation

Next, our skilled engineers and designers create customized dies and molds to match the specific requirements of each component. These molds are meticulously designed to ensure accurate dimensions, proper gating, and minimal defects.

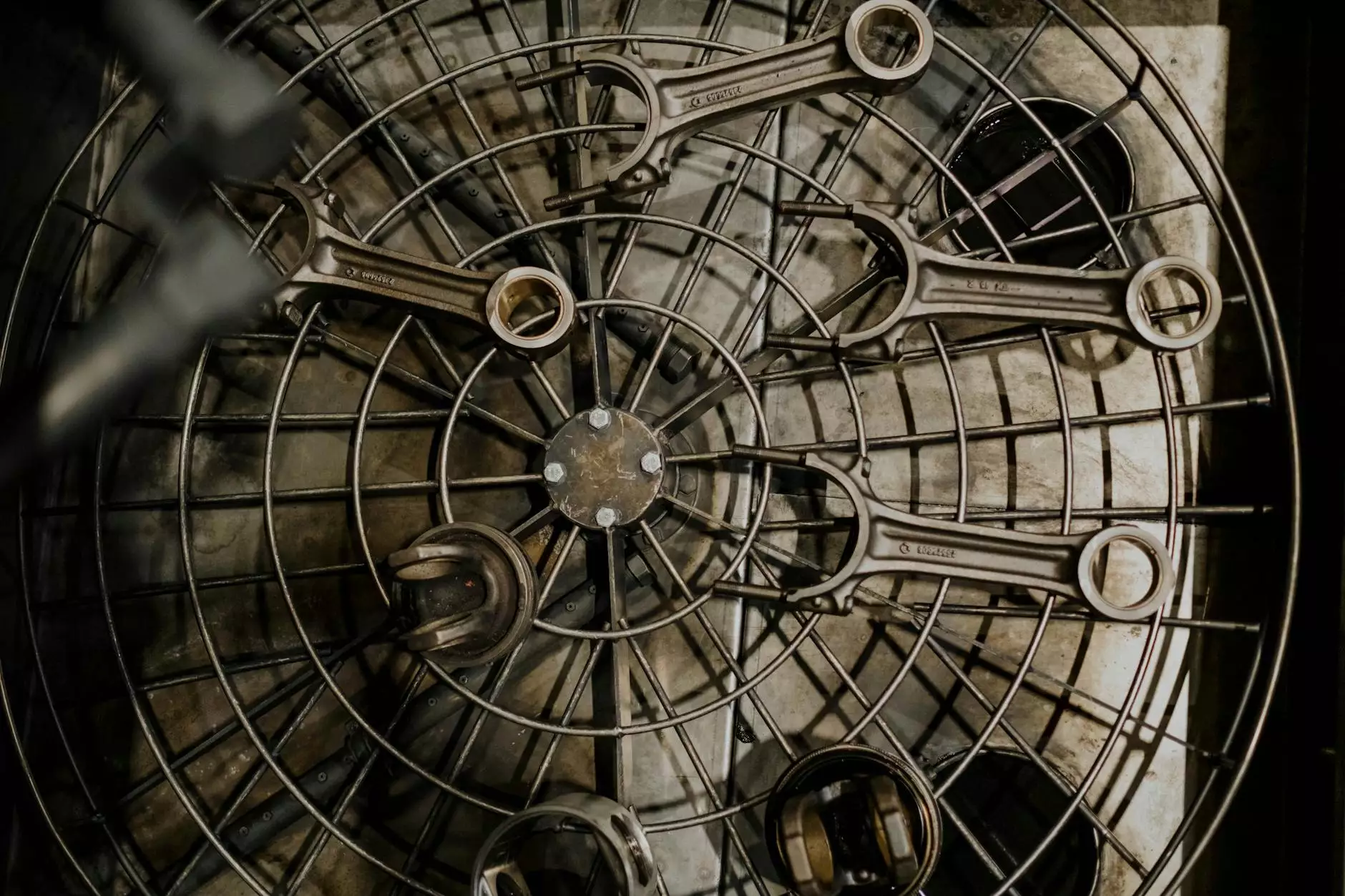

Die Casting Process

Once the molds are prepared, the die casting process begins. Molten aluminum is injected into the mold under high pressure, allowing it to fill all the intricate cavities and channels. The metal solidifies rapidly, resulting in a detailed and dimensionally accurate part.

Finishing and Surface Treatment

After the die casting process, we apply various finishing techniques to enhance the appearance and functionality of the parts. Options include precision machining, shot blasting, powder coating, anodizing, and more. These treatments help improve the overall aesthetics, durability, and corrosion resistance of the final product.

Meeting Your Specific Requirements

At Wetron Industrial, we understand that every client has unique needs and specifications. That's why we offer comprehensive customization options for our aluminum die casting parts. From material selection to surface finishes, we work closely with our clients to deliver tailor-made solutions that meet their exact requirements. Our team of engineers and technicians ensures that every part leaving our facility undergoes strict quality control checks to guarantee precision and reliability.

Why Choose Wetron Industrial as Your Aluminum Die Casting Part Manufacturer?

- Extensive Industry Expertise: With years of experience in the industry, we have gained in-depth knowledge and expertise in manufacturing aluminum die casting parts.

- Advanced Manufacturing Facilities: Our state-of-the-art manufacturing facilities are equipped with high-tech machinery and tools, allowing us to deliver top-quality parts consistently.

- Quality Assurance: We adhere to strict quality control measures throughout the entire manufacturing process to ensure that our parts meet and exceed industry standards.

- Customization Flexibility: We understand the importance of customization in meeting diverse industry needs. Our team is dedicated to providing tailored solutions to match your specific requirements.

- On-Time Delivery: We recognize the significance of timely delivery in today's fast-paced business environment. We strive to meet our clients' deadlines without compromising on quality.

Contact Us Today

If you're searching for reliable and trusted aluminum die casting part manufacturers, look no further than Wetron Industrial. Our commitment to excellence, exceptional craftsmanship, and dedication to customer satisfaction make us the ideal partner for all your die casting needs. Contact us today and let us discuss how our expertise can benefit your business.